Scientists at the Department of Energy’s Oak Ridge National Laboratory have developed a coating composed of carbon nanotubes that imparts superlubricity to sliding parts. It reduces the friction of steel rubbing on steel at least a hundredfold. An article about the coating is published in the magazine Materials Today Nano.

Superlubricity is the property of showing virtually no resistance to sliding; its hallmark is a friction coefficient of less than 0.01. In comparison, when dry metals slide against each other, the coefficient of friction is about 0.5. With an oil lubricant, the coefficient of friction drops to about 0.1. However, the ORNL coating reduced the coefficient of friction well below the cutoff for superlubricity, down to 0.001.

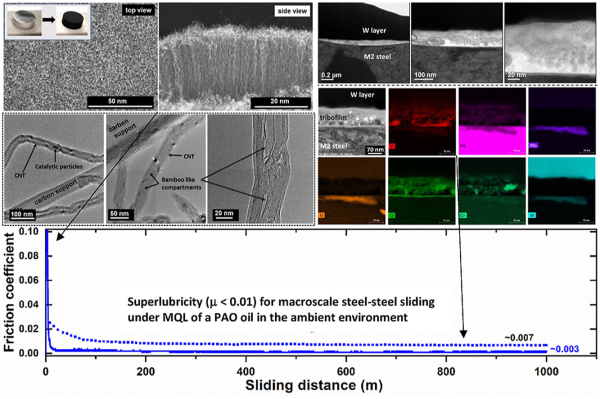

For the study, the researchers grew carbon nanotubes on steel plates, then using a machine called a tribometer, caused the plates to rub against each other to generate shavings of carbon nanotubes.

Multi-walled carbon nanotubes coat the steel, repel corrosive moisture and act as a lubricant reservoir. When first deposited, vertically aligned carbon nanotubes lie on the surface like blades of grass. When the steel pieces slide against each other, they essentially “cut the grass”. Each leaf is hollow, but made of multiple layers of coiled graphene, an atomically thin sheet of carbon arranged in adjacent hexagons like chicken wire. Fractured carbon nanotube debris from the chip is redeposited on the contact surface, forming a graphene-rich tribofilm that reduces friction to almost zero.

Kumara et al.

The new nanotubes do not provide superlubricity until they are damaged.

Carbon nanotubes are destroyed by friction, but become something new. The key part is that the fractured carbon nanotubes are pieces of graphene. These pieces of graphene are smeared and connected in the contact area, becoming what we call a tribofilm, a coating formed during the process. Both contact surfaces are then covered by a graphene-rich coating. Now, when they rub against each other, it’s graphene on graphene.

—Jun Qu, leader of the Surface Engineering and Tribology group at ORNL and corresponding author

The presence of an oil drop is crucial to achieve super lubricity.

We tried it without oil; it didn’t work The reason is that, without oil, friction removes the carbon nanotubes too aggressively. Then the tribofilm cannot form well or survive for long. It’s like an engine without oil. It smokes in minutes, while one with oil can easily run for years.

—Jun Qu

The superior slippery of the ORNL coating has an endurance capacity. Super lubricity persisted in tests of more than 500,000 rubbing cycles.

The researchers have applied for a patent on their new superlubricity coating.

The ORNL Laboratory Directed Research and Development Seed Program provided initial support for the proof-of-concept work. The DOE EERE Office of Solar Energy Technologies and Vehicle Technologies Office then supported further research.

Resources

-

Chanaka Kumara, Michael J. Lance, Jun Qu (2023) ‘Macroscale superlubricity using a sacrificial carbon nanotube coating’, Materials Today Nano doi: 10.1016/j.mtnano.2022.100297.