Newswise – Scientists at the Department of Energy’s Oak Ridge National Laboratory have invented a coating that could dramatically reduce friction in common load systems with moving parts, from vehicle drive trains to wind and hydroelectric turbines. It reduces the friction of steel rubbing on steel at least a hundredfold. The new ORNL coating could help fuel an American economy that loses more than a trillion dollars each year to friction and wear and tear, equivalent to 5% of the gross national product.

“When components slide against each other, there is friction and wear,” said Jun Qu, leader of ORNL’s surface engineering and tribology group. Tribology, from the Greek word for rub, is the science and technology of interacting surfaces in relative motion, such as gears and bearings. “If we reduce friction, we can reduce energy consumption. By reducing wear and tear, we can extend the life of the system for better durability and reliability.”

The superior slippery of the ORNL coating has an endurance capacity. Super lubricity persisted in tests of more than 500,000 rubbing cycles. Kumara tried continuous sliding performances for three hours, then a day and later 12 days. “We still have super lubricity,” he said. “It’s stable.”

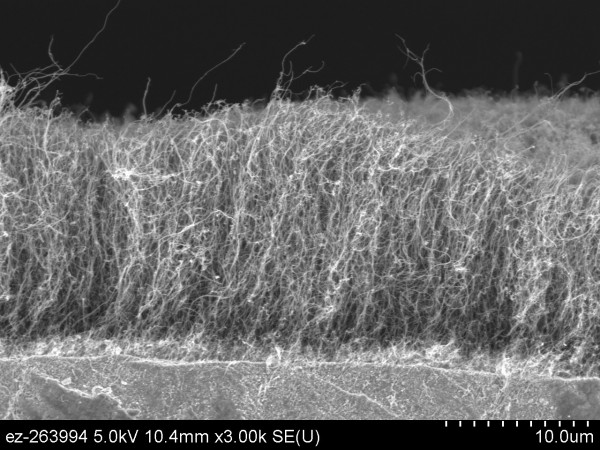

Using electron microscopy, Kumara examined the cut fragments to show that tribological wear had cut the carbon nanotubes. To independently confirm that rubbing had shortened the nanotubes, ORNL co-author Lance used Raman spectroscopy, a technique that measures vibrational energy, which is related to atomic bonding and crystal structure of a material

He added, “Somewhere, you can find a scientist with experience in carbon nanotubes, a scientist with experience in tribology, a scientist with experience in materials characterization. But they are isolated. Here at ORNL, we are together.”

ORNL’s tribology teams have done award-winning work that has attracted industry associations and licensing. In 2014, an ionic antiwear additive for fuel-efficient motor lubricants developed by ORNL, General Motors, Shell Global Solutions, and Lubrizol won an R&D 100 Award. ORNL contributors were Qu, Huimin Luo, Sheng Dai, Peter Blau, Todd Toops, Brian West, and Bruce Bunting. The Office of Vehicle Technologies in DOE’s Office of Energy Efficiency and Renewable Energy, or EERE, sponsored the research.

Similarly, the work described in the current paper was a finalist for an R&D 100 award in 2020. And the researchers have applied for a patent on their new superlubricity coating.

“Next, we hope to partner with industry to write a joint proposal to the DOE to test, mature and license the technology,” Qu said. “A decade from now we’d like to see high-performance vehicles and improved power plants with less energy lost through friction and wear.”

The title of the paper is “Macroscale superlubricity using a sacrificial carbon nanotube coating”.

The ORNL Laboratory Directed Research and Development Seed Program provided initial support for the proof-of-concept work. The DOE EERE Office of Solar Energy Technologies and Vehicle Technologies Office then supported further research.

UT-Battelle manages ORNL for the DOE Office of Science, the leading proponent of basic physical science research in the United States. The Office of Science is working to address some of the most pressing challenges of our time. For more information, visit energy.gov/science. — Dawn Levy