Throw as much stock (or shade) as you like at the six-cylinder engine, there’s no getting around the fact that it’s long been known as the Swiss Army Knife of engines. Whether it’s an angled V6, a brutal Boxer, the Slant-6, or one of the iconic inline-six designs, drivers around the world have embraced this piston middle ground with open arms.

Today, modern advances such as cylinder deactivation and direct injection have made the six-cylinder’s efficiency better than ever. With twin turbochargers delivering V8 power figures, the venerable V6 in particular continues to be hailed as the future of practical performance and power.

But automakers have also begun to show revived interest in the much more streamlined and much more rectangular inline-six engine. Even smaller manufacturers like Mazda have recently announced investment production of six cylinders in lineproving that the streamlined six-in-line setup is far from obsolete.

However, to appreciate what the modern inline six has to offer, we should probably revisit the damn near-indestructible blue Oval iron block beast that paved the way. Because if it weren’t for this simple but effective American-made slab of engineering, who knows where our interest in the straight six might be…

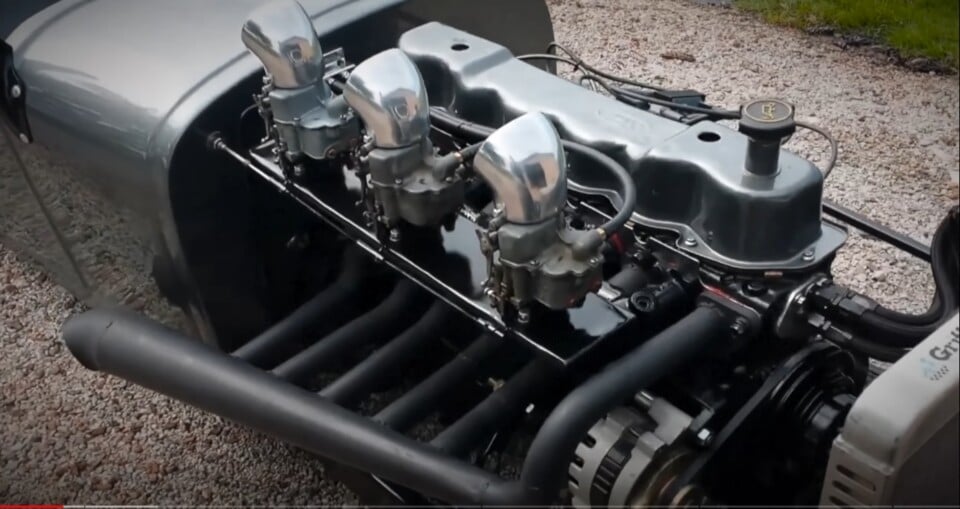

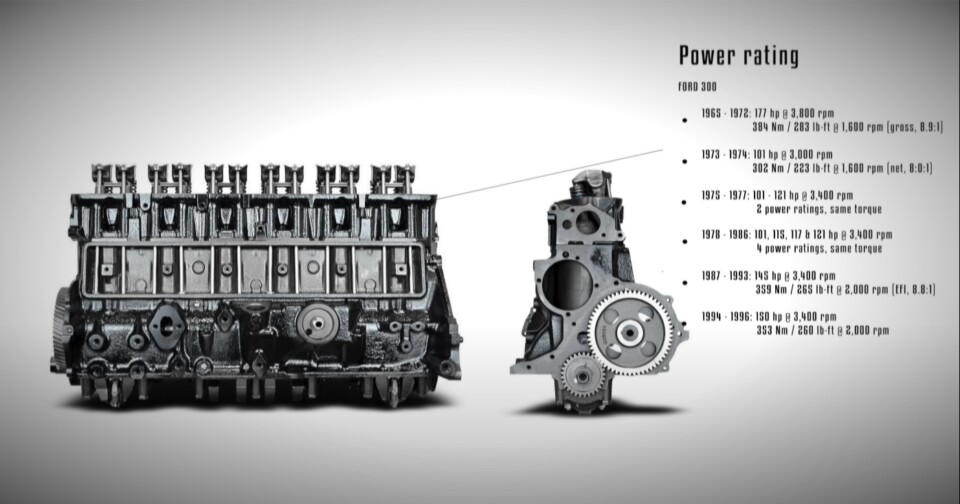

Fuel efficiency ratings were in the 15-25 mpg range on most vehicles equipped with a Ford 300, and many vehicle owners saw more than 300,000 miles of use before engine removal was required. engine Photo credit: VisioRacer/YouTube

Forget the Germans… Ford is firing on all six cylinders

While European luxury automakers may have maintained an interest in the straight-six more than any other, it was Ford that made the best-selling engine design. An inline six-cylinder success story that was never intended for racing glory or world records, but for mass appeal. Yes, we mean the classic Ford 240 and its much bigger and more brutal sibling, the mighty 300.

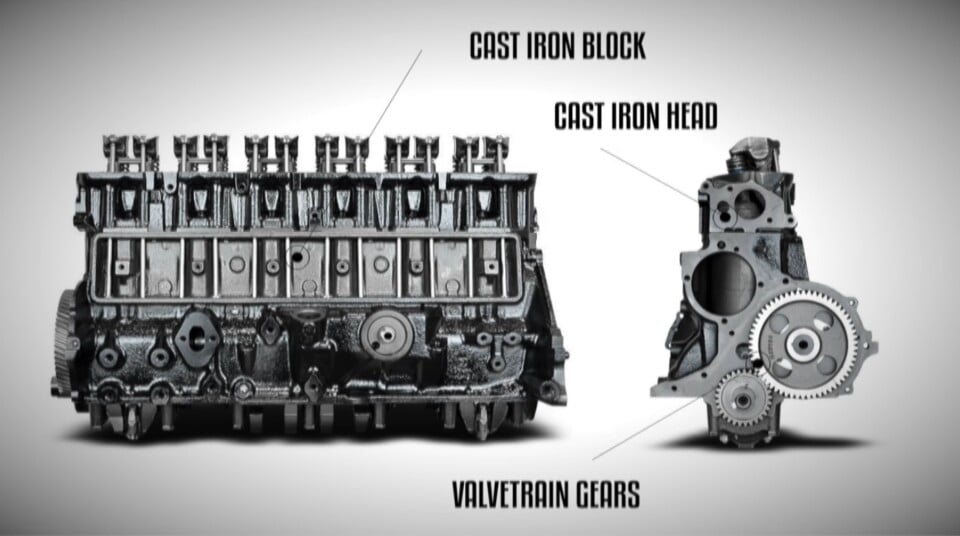

With its cast-iron cylinder head and overhead valve block, triple-ring aluminum pistons, forged connecting rods, hydraulic lifters and four-bearing cams, the single-carb six provided reliable power in a much smaller environment (and affordable) package than the brand’s V8 engines. Naturally, these smaller engines were an instant hit with Ford buyers, with the 240 and 300cc duo gracing a myriad of platforms from the mid-’60s onward.

Photo credit: VisioRacer/YouTube

A bit of an anomaly today (and not to mention a fire hazard), both the 240 and 300 variants featured a non-crossflow header, which routed the intake and exhaust port holes to the same side . However, due to its lower performance potential, the 240 variant was eventually phased out after a decade more or less production, leaving the iconic 4.9-litre 300 to reap all the rewards.

Photo credit: VisioRacer/YouTube

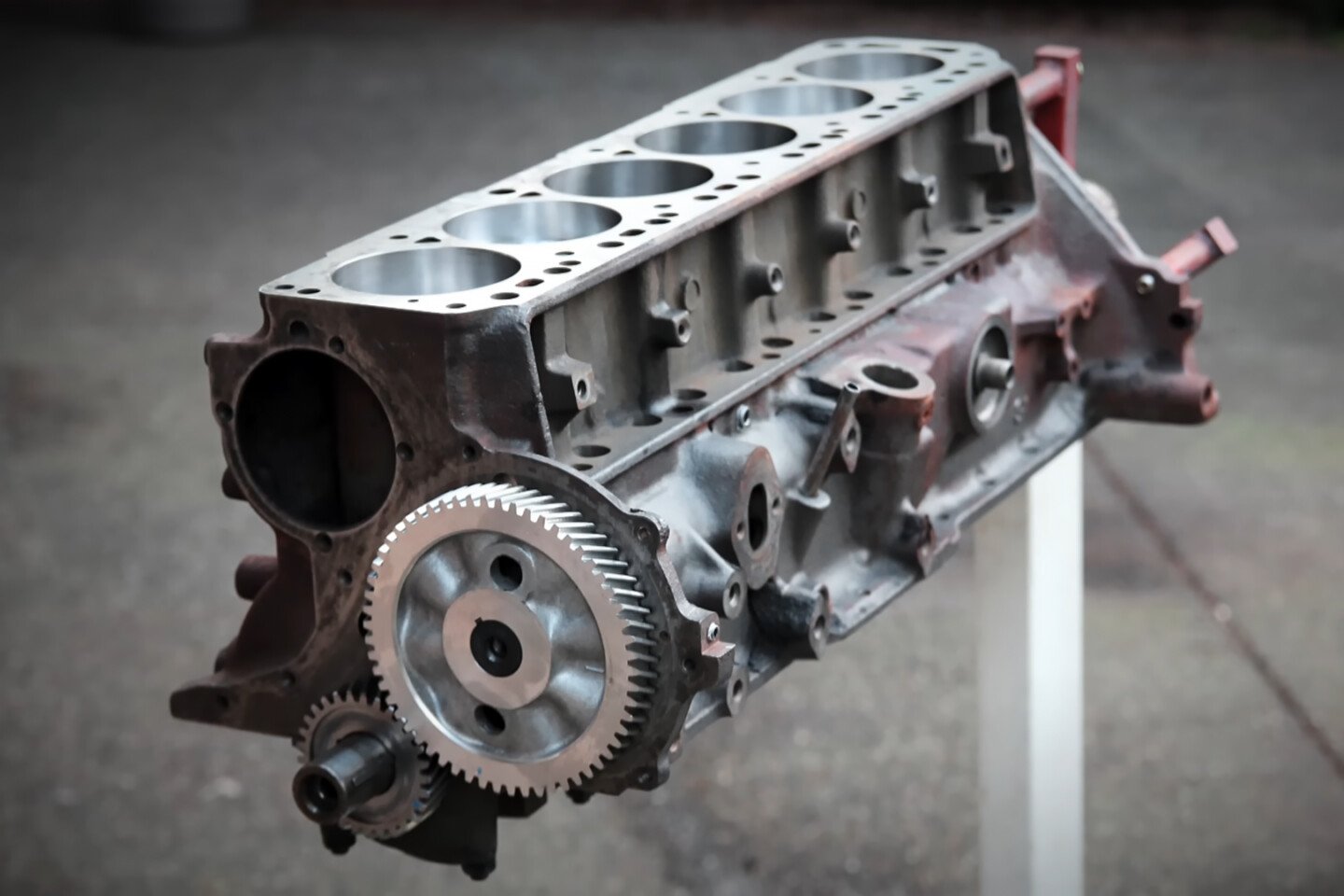

The bigger 300 block sported a beefier bottom end with seven main bearings and a noticeably larger one. 78cc D-shaped combustion chamber design on top. This allowed an 8.8:1 compression ratio to produce more power within each cylinder. On the downside, this also meant that premium pump gas was pretty much mandatory, as anything less usually resulted in detonation and a nasty carb.

But while the power figures remained ridiculously low, the 300’s performance prowess could be felt within its torque figures, which could be had at a modest 1,600 rpm. Considered lukewarm by today’s standards, the torque inside the Ford 300 was quite impressive for the time. This made the economical inline six-cylinder engine an ideal choice for a wide range of drivers as well as companies that depended on heavy vehicles.

The Ford 4.9 L 300 engine proved to be so reliable, it was even sourced as a crate engine, where it was later stuffed into tractors, oil well pumps, generators, sawmills, snowplows and a whole host of other non-DOT- approved applications. Photo credit: VisioRacer/YouTube

The staying power of six straights has been explained

From 1965 and well into the latter part of the last century, Ford’s simple straight-six design provided farmhands with the tow and torque they needed, and hot rod hellhounds with an easy high-octane engine swap. available and cheap.

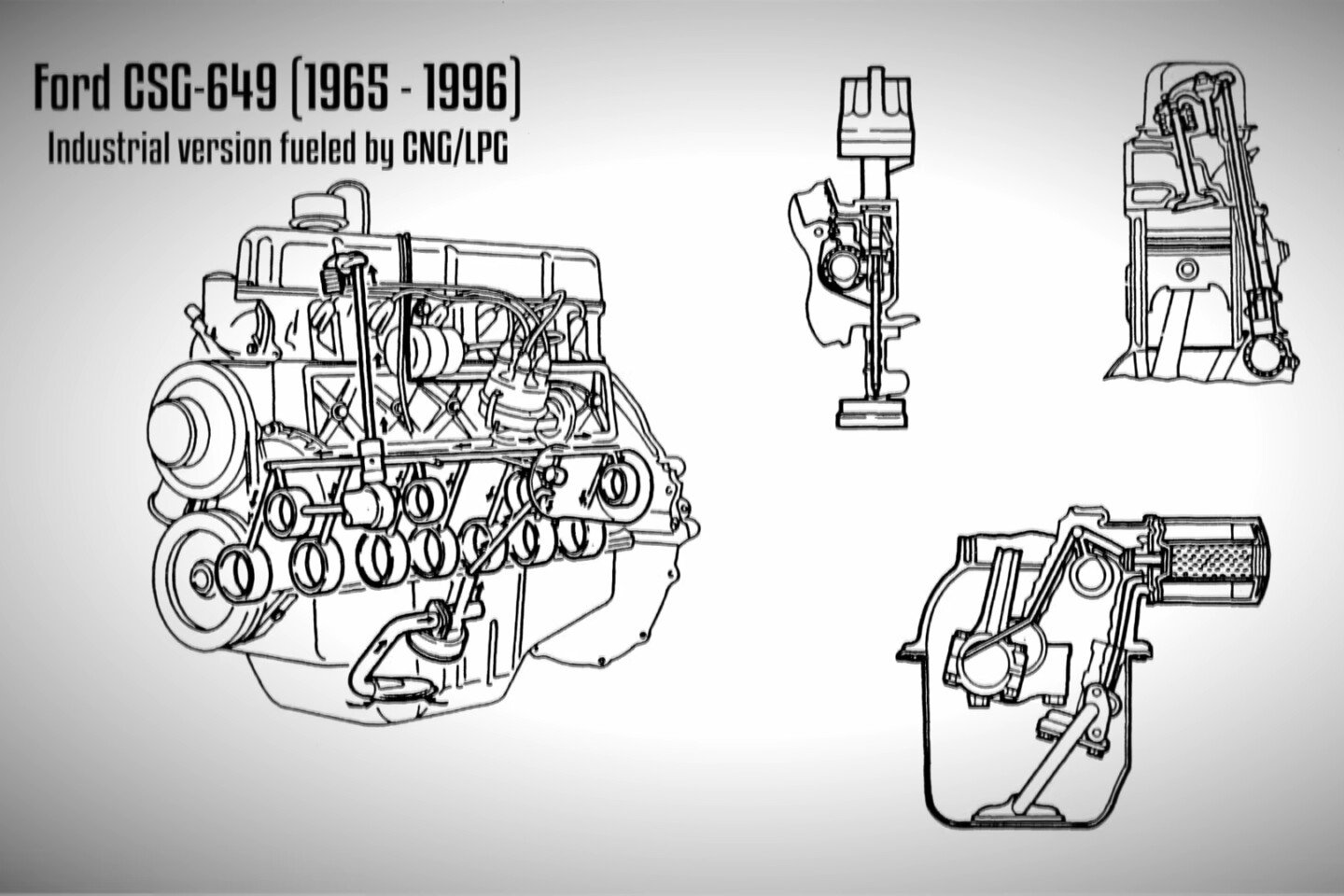

Commercial vehicles and delivery vans also benefited greatly from the vintage 300, as the torque-rich petrol engine performed well in cold weather and hauled heavy loads like a diesel. In addition, both compressed natural gas (CNG) and liquefied petroleum gas (LPG) could be used to power industrial applications.

With a thicker water pump shaft, stout harmonic dampers, a much larger six-quart oil tank and a redesigned set of tough pistons, the late-model HD version of the 300 in particular proved to be nearly indestructible when properly maintained.

Also, this engine was the only variant to use a steel cam gear design, as opposed to the lighter (and much weaker) fiber gears found on the non-HD models. Mmmm… fiber based engine gears. I wonder if Ford originally planned to match this design with their papier mache camshafts…

Caption: While European luxury automakers have long favored the inline-six design and Ford made the most of the 300’s mandate, Japanese and Korean automakers have barely used it engine out of the occasional sports car or prototype vehicle. Photo credit: VisioRacer/YouTube

fast ford

By 1978, Ford had the 300’s 4.9-liter moniker locked in, along with the use of a simplistic ECU for timing and emissions control purposes. This was soon followed by the introduction of an OBD-I diagnostic plug in 1981, which benefited greatly from a widespread conversion to fuel injection in 1987.

With its respectable fuel efficiency ratings (both before and after the introduction of fuel injection), period-appropriate torque figures, and a simple design that supported easy maintenance and reliability, the Ford 300 from 4.9 liter remained widely revered as one of the most reliable in line. six-cylinder engines of all time.

Now let’s see if Ford decides to resurrect the Rod inline six that it made between 2002 and 2016 for the Australian market…

The inline-six engine’s superior balance in both primary and secondary stages makes it a rock star in terms of both smoothness and linear power delivery. It’s also not as bulky as the block V6, and for many mechanics, it’s a much simpler service affair. Photo credit: VisioRacer/YouTube