Introduction to hydrogen engines

A hydrogen engine (HCE) is an engine that uses hydrogen (H2) as fuel. It is a modified gasoline engine, but it does not emit any carbon-based pollution, which is a huge benefit for carbon neutrality. It is also vital to remember that HCEs vary from hydrogen fuel cells in which the former receive their energy through the combustion of hydrogen, while the latter obtain it through electrochemical processes.

HCEs operate similarly to 4-stroke gasoline engines (ICEs). But compared to gasoline, which has an octane rating of 90 (for premium gasoline), hydrogen has a higher octane number of 130. As a result, HCEs have a higher air-fuel ratio of 180 :1 compared to ICEs. ratio of 37:1. So cars can run on lean mixtures (less fuel more air). The ionization energy for HCEs is generally 0.02 mJ versus 0.24 mJ for ICEs. Compared to ICEs, HCEs also have higher flame velocities, leading to faster combustion. Also, hydrogen has an auto-ignition temperature of 500°C compared to 250°C for ICEs, allowing HCEs to have higher compression ratios. Due to the increased diffusivity of hydrogen, the air-fuel combination will mix more effectively and quickly. In addition, the extinction distance is shorter (the distance between the cylinder walls and the maximum point where the combustion flames reach). This ensures that the entire air-fuel combination is burned.

Since the first engine was created in 1806, hydrogen engines are not a recent invention. However, adoption was only passive due to high hydrogen costs and safety concerns with HCEs. The search for alternative fuels has sparked interest.

Tata Nexon EV Max #DARK: Rs 19.04 lakh for new wheels, bigger touchscreen and more | TOI Auto

Market overview, expectations and associated challenges

The HCE market is currently valued at USD 18.22 billion in 2023 and is projected to be valued at USD 46.31 billion by 2033 with a high-paced CAGR of 9.78 percent according to a report recent from Future Market Insights. The major contribution is expected from North America, Europe and APAC regions.

In the automotive sector, the adoption of electrification has reached unprecedented levels. The transition to BEVs has not been successful in industries such as mining, agriculture and other off-road applications, which demand higher power outputs 24 hours a day while being exposed to intense vibration and heat generation. To decarbonise engines, it is envisaged that diesel engines would be immediately replaced by HCE.

The transition to HCE presents some difficulties that OEMs, Tier-1s and other companies must resolve.

- Because hydrogen has a very small molecular structure and can escape, current materials cannot be used for HCE without the risk of fires. The engine will be subjected to extremely high thermal and structural stresses, since the air-fuel ratio of HCEs is 6 times greater than that of ICEs. In addition, they will experience hydrogen embrittlement (cracking). As a result, it is important to look for replacement materials for parts such as camshafts, cylinders, valves, injectors, pistons, liners, crankshafts, fuel systems, storage units, etc. that can host hydrogen as fuel.

- Due to the need for 12 times less ionization energy than gasoline, hydrogen is highly flammable. To prevent accidents due to low ionization energy and mishaps caused by hydrogen escaping through cylinder inlet valves, strict safety mechanisms such as redundant arrangement for shut-off and safety valves, the oversizing of components exposed to pressure and the barrier concept (double wall construction) for hydrogen tanks must be taken into account at the concept stage.

- Although HCEs are carbon neutral in their emissions, they still emit small amounts of NOx. To make HCEs completely emission-free, specific SCRs (selective catalytic reductions) need to be designed.

- The identification of non-combustible engine lubricants should also be noted, as the burning of lubricants releases minute amounts of hydrocarbon-based pollutants due to the increased combustion temperature of hydrogen within the HCE.

- Hydrogen production is another important issue. The effort to develop a cleaner fuel misses the mark because 95 percent of the hydrogen currently produced comes from natural gas and fossil fuels (gray hydrogen) and there are only 800 refueling stations in operation worldwide the world.

Key market players

OEMs and Tier 1 suppliers have already started adopting HCE. Companies such as BorgWarner and Cummins in the US have already started making investments in hydrogen engines. However, Cummins showcased its hydrogen engine at the recently held Indian Auto Expo 2023, Greater Noida, India. Westport Fuel Systems is actively developing HCE for heavy vehicle applications in Europe.

Toyota has made available the Corolla Cross HCE concept vehicle. Toyota and Yamaha are also developing a hydrogen-powered 5.0-liter V8 engine. It will have a power of 450 hp at 6500 rpm. Japanese car manufacturers such as Mazda, Subaru and Kawasaki Heavy Industries have also begun their study in this area. The H2-ICE trucks were also showcased by Ashok Leyland, an Indian commercial vehicle OEM at the Auto Expo 2023. They also showcased the H2-ICE truck at the India Energy Week 2023 along with Reliance Industries.

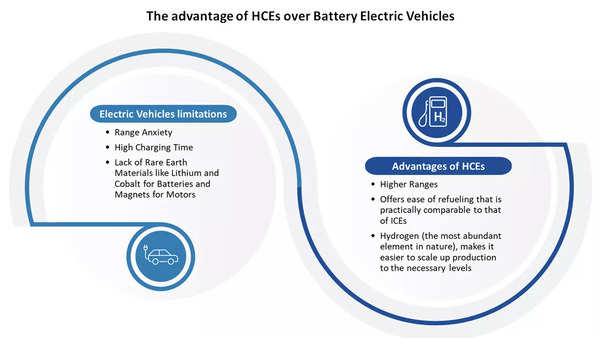

Advantages of hydrogen engines over electric vehicles

conclusion

The automotive sector is competing in a parallel marathon using a variety of technologies to find the ideal substitute for fossil fuels. Strict regulations imposed by government agencies force OEMs and Tier 1s to meet strict emission standards. The best alternative, in this case, are hydrogen engines. Compared to ICE, hydrogen engines require about the same amount of time to refuel, but the latter has the main advantage of being carbon neutral.

However, for this change to be economically viable, significant resources and efforts are required. The transition to HCEs is happening more slowly, as OEMs and Tier-1s are still substantially dedicated to conventional engines, while electrification is still their main focus. Therefore, it is crucial to determine the extent of hydrogen engines from the beginning and make the necessary preparatory expenses in this technology.

For companies to build the infrastructure needed for HCEs, such as hydrogen plants that create green hydrogen and refueling stations, government support around the world is crucial. It is also necessary to implement incentives such as tax credits to help companies expand their operations.

Emphasis should also be placed on educating target consumers through advertising to encourage the purchase of HCE cars. When these steps are achieved, HCEs will be economically viable and have a competitive advantage over other technologies.