A team at the Southwest Research Institute (SwRI) has developed a mechanical test device to analyze fluids and lubricants formulated for electric vehicles. The team modified a commercial tribology testing device to give it the ability to assess the impact of electrical currents on fluids, measuring the wear and friction of automotive parts in the presence of stress applied

The electrification of the automotive industry has accelerated in recent years, with future projections showing exponential growth in market share for both light and heavy-duty applications. Traditional fluid testing tools, however, were not developed to effectively analyze lubricant properties in electrified environments. This also extends to tribology testing.Cole T. Frazier, Research Engineer, SwRI’s Advanced Transmission Lubricants Section

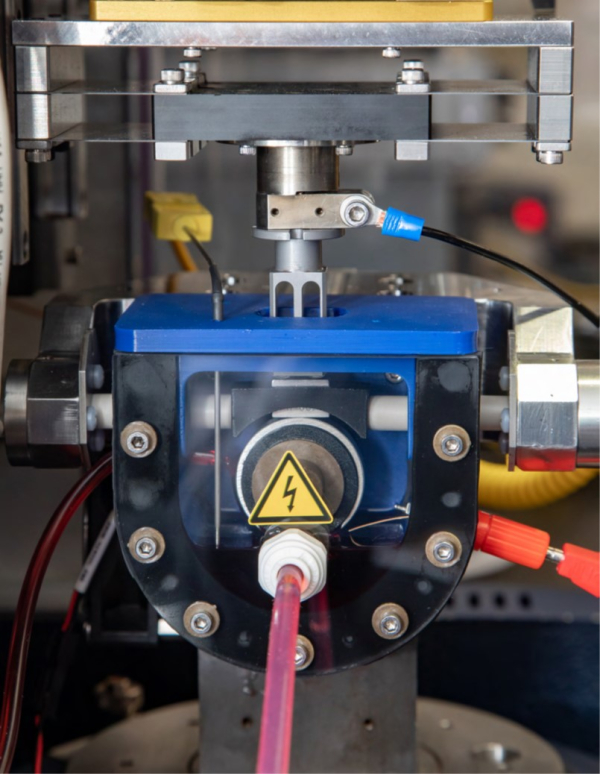

Tribology is the study of friction, lubrication and wear. The challenges in evaluating the behavior of electric vehicles is the presence of an electric potential applied to the interfaces of components and lubricants. To face this challenge, Dr. Carlos Sánchez, a senior research engineer in SwRI’s Tribology Research and Evaluations section, designed a new test rig to model the effects of electrification on rotating parts.

This small-scale test bench was built around a traditional universal testing machine. The test setup and protocol were developed by the team throughout the project.

An internally funded SwRI project modified a commercial tribology testing machine to more effectively analyze the friction and wear associated with lubricants formulated for electric vehicles. The new tool adds to SwRI’s testing capabilities and enables the lubricant industry to efficiently test and optimize lubricant formulation. Courtesy of Southwest Research Institute

The multidisciplinary team included Frazier, Sanchez, Nolan Erickson (Electrical Engineer), Dr. Peter Lee (Institute Engineer), Andrew Velasquez (Engineer) and Travis Kostan (Principal Research Analyst).

Most electric vehicles use alternating current (AC) or permanent magnet induction motors, which are powered by on-board battery packs. An inverter takes the direct current (DC) voltage input from the batteries and converts it into the AC power needed to run the vehicle’s engine.

The many rotating surfaces of electric vehicles are exposed to voltage spikes during the DC to AC conversion process. Spikes and the electric field inherent in high-voltage environments can allow electrical currents to flow across surfaces, damaging the lubricants and materials that keep them moving smoothly.

– Carlos Sánchez

According to the researchers, the frequency conversion rate from DC to AC can cause local voltage spikes that require grounding. Motor bearings are often particularly susceptible to electrical currents flowing through them due to their location near voltage peaks. The electrical potential of the bearings can build up until the voltage becomes strong enough to break the thin film of lubricant that separates the small metal ball bearings from the raceways or bearing housing, which can cause damage to the surface and scars.

The team developed and analyzed a test protocol for the new instrument that would best represent the real system and produce relevant results. Using this internally funded new breakthrough, they tested several different commercial lubricants and measured wear scars and friction on raceways and bearing housings. They found that the electrical potential through a fluid, whether the current is AC or DC, can affect bearing wear and friction by up to 20%.

SwRI specializes in building custom tribology equipment and testing capabilities to enable the industry to test multiple lubricant formulations efficiently, without requiring large-scale testing. In this case, because lubricant breakdown is shown to be fluid-dependent, formulators can optimize their lubricants for specific EV drivetrains. SwRI’s bench-scale testing capabilities will accelerate lubricant optimization, improving durability and increasing vehicle range by reducing friction.

—Peter Lee

The modifications and initial results were presented at the 2022 Society of Tribology and Lubrication Engineers (STLE) Annual Conference, the 2022 STLE E Mobility Conference, the Tribology Gordon Conference, and the Sustainability Conference of the Institution of Mechanical Engineers. Full results will be presented at the STLE Annual Meeting in Long Beach May 16-20, 2023.

SwRI also hosts the Advanced Fluids for Electrified Vehicles Consortium, designed to advance the industry’s understanding of the unique stressors placed on electric and hybrid vehicle fluids.