HydroGraph Clean Power Inc. (CSE: HG) is continuing the transition from a research and development company to commercializing its game-changing Hyperion Graphene Production System for its initial target markets.

The Hyperion system can produce graphene with a pure carbon content of 99.8% with identical and consistent production quality with minimal energy use, no solvents and zero carbon emissions, making it one of the leading producers of cleanest graphene in the world. The company is one of four graphene producers that have been verified by the Graphene Council and the only US producer.

TO READ: HydroGraph enters the final testing phase for the graphene production unit

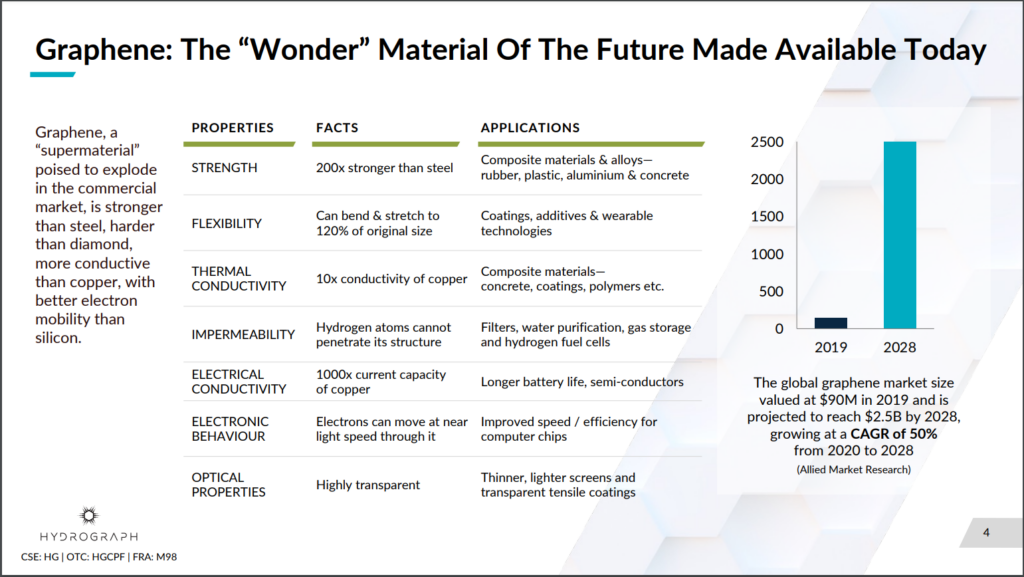

Graphene is a one-atom-thick two-dimensional sheet of hexagonally coordinated carbon atoms and is considered a “supermaterial” that is stronger than steel, harder than diamonds and more conductive than copper. It can be incorporated into existing products and technologies, thereby enhancing and/or enhancing their performance and service life characteristics while providing users with economic and technological advantages over their competitors. Vantage Market Research projects that the global graphene market will grow to a $2.5 billion industry by 2028.

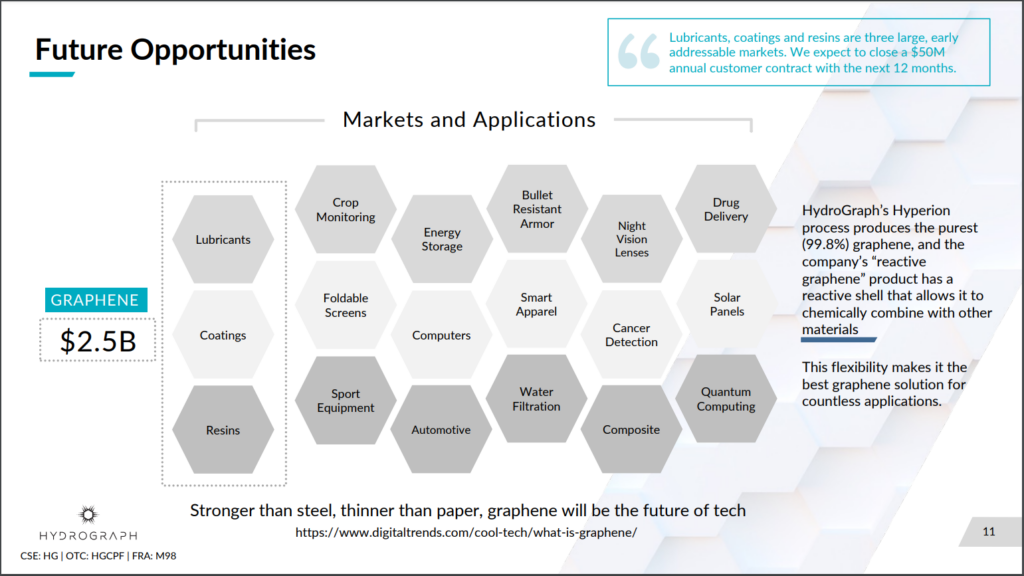

Graphene can be infused into a wide range of products to greatly improve product durability, strength and performance. HydroGraph’s Hyperion system is currently being commercialized with a focus on three initial target markets; resins, lubricants and coatings. The CEO of HydroGraph, Mr. Stuart Jara, has over 20 years of senior executive experience and credibility in these industries. As part of its January 12, 2023 shareholder update, Jara disclosed that the company has shipped graphene samples and secured nearly 12 active NDAs with potential customers who are testing graphene infusion in some of their products, with the aim of entering into long-term business. graphene supply contracts.

The angle of the lubricant

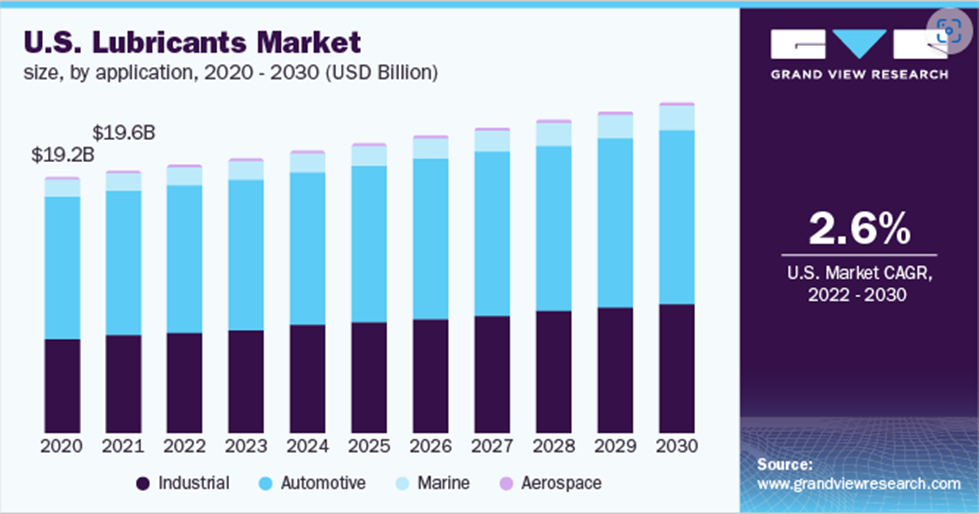

Graphene can help reduce the coefficient of friction, reduce heat caused by friction, and increase the efficiency and longevity of lubricants. Grandview Research projects that the US$128 billion lubricants industry will continue to grow at a CAGR of 3.7% through 2028, driven by growing demand for higher performance lubricants. The lubricants industry is massive and dominated by large multinational corporations such as ExxonMobil, Chevron, British Petroleum, Royal Dutch Shell, Sinopec and many more.

To address the industry opportunity, Hydrograph has appointed Jennifer Carmichael as Director of Business Development – Lubricants and Specialty Chemicals, to lead business development activities within the segment. After graduating Summa Cum Laude with a Bachelor of Science in Industrial Chemistry from the University of Houston, he has accumulated over 13 years of experience in product development, marketing and business growth.

Prior to joining HydroGraph, Carmichael held a number of strategic roles in energy and specialty chemicals, most recently with global oil services giant Schlumberger, as global account manager for ExxonMobil and Chevron, where he was responsible for develop and execute global business strategies for key accounts. As someone who has worked in the industry for many years, Carmichael has the knowledge of the industry, understands the challenges to be addressed and has the relationships to accelerate market penetration, sales growth and profitability.

Motor oil is the largest segment of the lubricant market and is required to improve engine performance and efficiency, as well as to meet ever-changing emission standards and other environmental protocols. According to a report by Transparency Markets Research, automotive oils accounted for 54.6% of the lubricants market in 2021. Lubricants are widely used in manufacturing, power generation and a multitude of industrial activities to reduce wear and tear on machinery, reduce maintenance costs, address safety, increase efficiency and productivity. Infusing lubricants with graphene can greatly improve the performance and longevity of equipment in almost any situation.

A major advantage for graphene-infused lubricant applications is that a very small amount of graphene can be added to a lubricant to achieve the full impact of improving the performance characteristics of the lubricant. This negates the need for multiple chemical additives that may or may not achieve the same desired results. On its own, graphene can improve lubricant and machine performance, safety, reliability, longevity and cost, all with a favorable environmental impact compared to alternatives.

Graphene can offer the following improvements for lubricating oils;

- Reduces Friction: Tests have shown a friction factor reduction of up to 55%

- Reduces mechanical and thermal wear: tests have shown a decrease in mechanical wear by up to 70%

- Helps prevent corrosion

- Improved lubricant stability and performance under high temperature, shear and pressure conditions

- Increases the longevity of the lubricant and engine components, thereby reducing the frequency of oil changes and engine maintenance.

- Improves fuel efficiency and machine performance

HydroGraph’s graphene in particular has shown excellent performance in lubricant applications, including reducing friction by up to 55% and decreasing mechanical wear by up to 70%. More performance data is expected to come from the company’s ongoing research and development.

Other markets

More broadly and in addition to lubricants, HydroGraph and its potential customers are testing graphene in a variety of applications within other initial target market segments that could be commercially launched in the near future. In this regard, Hydrograph has appointed Randall Zajac as Director of Business Development of Resins and Composites, who will be responsible for the growth of the resins and composites verticals.

According to Grandview Research, the global coatings market, which was valued at US$83 billion in 2021, is expected to grow at a CAGR of 3.5% through 2030. Meanwhile, the thermoplastic resin market is expected to grow by 7.7% to US$40. billion by 2030. Thermoplastics have higher heat tolerance, more fatigue resistance and are 30%-40% lighter than aluminum.

The modular model

One of the most significant and compelling aspects is HydroGraph’s modular model. HydroGraph’s Hyperion system can produce high-purity graphene on the market with a negligible capital cost of less than 5% of one year’s graphene sales based on its current figures. This is due to the unique nature of its patented modular graphene production technology.

The Hyperion system is elegant and simple. It is compact, scalable, modular, customizable, with no rotating equipment and a cost-effective “reactor unit”, producing graphene with almost 100% pure carbon content with minimal energy use, no solvents and zero carbon emissions. A chamber is filled with a hydrocarbon and oxygen, the mixture is ignited with a small spark and graphene is formed.

HydroGraph has a secondary bonding process that follows the Hyperion system to produce a reactive single-shell graphene on the outer layer that they call reactive graphene. This reactive graphene can be chemically combined with other products and can be easily integrated into a variety of products, including energy storage, lithium batteries, solar cells, supercapacitors, semiconductors, medicine and other applications.

HydroGraph has positioned itself as an enabler to help its customers grow their business, and will not be a direct competitor, simply a supplier of an essential raw material that improves products. It looks like the road to income is coming.

FULL DISCLOSURE: HydroGraph Clean Power is a client of Canacom Group, the parent company of The Deep Dive. The author has received compensation for covering HydroGraph Clean Power in The Deep Dive, with The Deep Dive having full editorial control. It is not a recommendation to buy or sell. We may buy or sell company securities at any time. Always do additional research and consult a professional before purchasing security.