Bentley will cease production of its 12-cylinder petrol engine in April 2024, by which time more than 100,000 examples of the iconic W12 will have been handcrafted at the company’s Dream Factory in Crewe, England.

The decision is part of Bentley’s acceleration towards a sustainable future through its Beyond100 strategy, which will see the company’s entire model line-up fully electrified by the start of the next decade, reducing average fleet emissions at 0 g/km of CO2.2. This has already begun, with the introduction of the Bentayga and Flying Spur Hybrid models, whose demand is exceeding the company’s expectations.

When production of the W12 ends next year, Bentley’s entire model line will be available with the option of a hybrid powertrain. Meanwhile, an engine first made available in the industry-defining Continental GT, which has been driving Bentley both metaphorically and literally for the past 20 years, will go down in history.

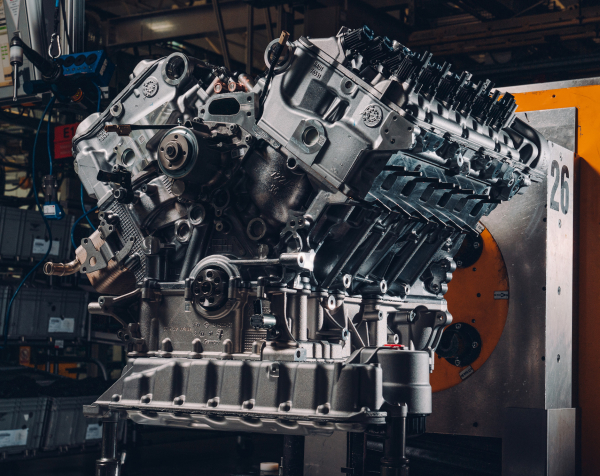

Development work has recently concluded on the most powerful version of W12 ever created. The latest iteration of this engine, destined for just 18 examples of the Bentley Batur to be handcrafted by Mulliner, is now confirmed to develop 750 PS and 1,000 N·m of torque. The increased torque figure forms Bentley’s typical “torque plate”, which runs from 1,750rpm to 5,000rpm, with peak power at 5,500rpm.

While all Baturs are sold, a limited number of the 659bhp version of the W12 engine offered in the Speed versions of the Continental GT, Bentayga and Flying Spur, as well as the Continental GT Mulliner and Flying Spur Mulliner. Demand for these final W12-powered Speed and Mulliner models is expected to be high.

Bentley’s aim is to recycle and redeploy the 30 specialist craftsmen who hand-assemble and test every W12 engine at Bentley’s carbon-neutral factory in Crewe. Meanwhile, the W12 engine production facility will make way for an expanded line to complement other Bentley engines used for plug-in hybrid models.

Since the first introduction of the twin-turbocharged 6.0-litre W12 in 2003, Crewe’s engineering team has continually improved the engine’s performance in terms of power, torque, emissions and refinement. Over the past 20 years, power has increased by 37% and torque by 54%, while emissions have fallen by 25%.

Initially this was through the evolution and optimization of control systems, improvements in oil and cooling designs, turbocharging technology and more effective injection and combustion processes.

For the Bentayga’s launch in 2015, the W12 was completely redesigned from the ground up, and it’s the version of the engine that remains in production today, with cylinder deactivation, direct injection and porting, and twin-scroll turbos.

A thoroughly reworked engine included a 30% stronger crankcase than its predecessor, while cylinder surfaces were coated to reduce friction and improve corrosion resistance. A low-alloy steel coating is applied to the holes using an atmospheric plasma spraying (APS) process.

Improvements were also made to the cooling system, with the engine having three separate coolant circuits. The former is designed to bring cylinder heads up to optimum operating temperature as quickly as possible for the best engine performance and low emissions. The second cools the engine block and oil system, while the third manages the thermal load on the turbochargers. Each system has a dedicated water pump, allowing optimized individual control.

The W12 combines high-pressure direct fuel injection (200 bar injection pressure) with low-pressure port injection (six bar). The combination of these two systems maximizes refinement, reduces particulate emissions and optimizes power and torque delivery.

Dual-scroll turbochargers minimize turbo response time and provide a more efficient exhaust package. The exhaust assemblies for the three front and three rear cylinders are separated from each other, feeding the twin-scroll impellers. The turbocharger housing is welded directly to the exhaust manifolds and includes built-in speed sensors, which allow the engine to monitor the performance of the turbo for maximum efficiency.

Bentley’s variable displacement system shuts down half the engine under defined conditions. Intake and exhaust valves, fuel injection and ignition are closed in defined cylinders, with the engine operating as a six-cylinder for improved efficiency. The system will operate in this mode in gears three through eight, below 3,000 rpm and up to 300 N·m of torque output.

For the final and definitive version of the W12, Mulliner’s engineering team has reworked the intake, exhaust and cooling systems to release more power and torque.

The turbochargers have a new design to improve efficiency, while the ducts that feed them air are 33 percent larger: at maximum power, the new engine ingests more than a ton of air (1,050 kg) per hour Larger charge air coolers, with 10mm increased depth and new core geometry, reject 35% more heat from pressurized intake air, further reducing intake temperature , which means a denser charge for more power.

The new intake and turbocharger system is combined with a greatly revised engine calibration to unleash the additional available torque, and the complete engine system is combined with a new transmission calibration to deploy the additional power and torque and improve the ‘driving experience.

The W12 engine plant will have delivered more than 105,000 engines before reaching 20th birthday this year