A serious in-flight incident highlights the danger of a maintenance error and the importance of knowledge and procedure to minimize it.

An Australian Transport Safety Bureau (ATSB) report into an incident in 2021 found that an aircraft’s fuel lines had been mistakenly transposed.

The Cessna 441 Conquest II turboprop aircraft, operating a charter flight in the Northern Territory, had to divert after the pilot observed abnormal engine indications.

The twin-engine aircraft was flying from Sawfish Camp to Darwin with 9 passengers when the pilot observed abnormal torque fluctuations, as well as high oil pressure and high oil temperature indications, from the right TPE-331 engine.

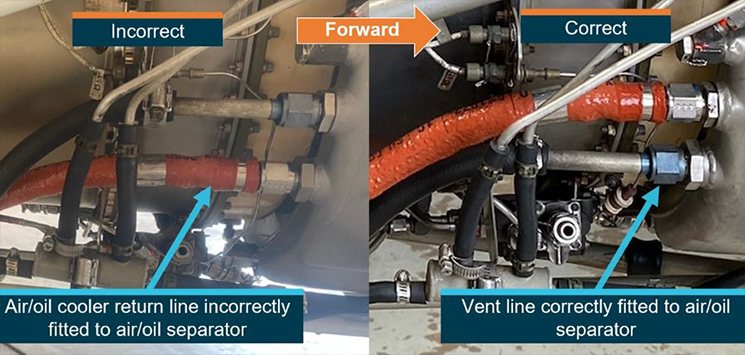

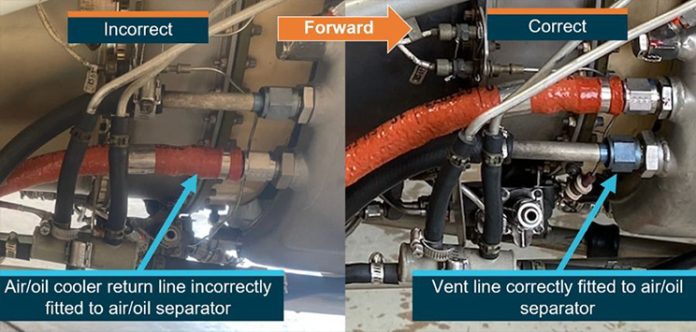

The pilot diverted the aircraft to Tindal Airport and landed without incident, with maintenance checks identifying that the air/oil cooler return line and the air/separator vent line oil had been transposed incorrectly during a recent engine change.

“The oil lines were easily transposed because they were long and flexible enough to reach any port, and they were the same size, used the same thread, and were almost identical in appearance,” said the safety director of the ATSB Transport Mike Walker.

However, since there was no record of which engineer had done the work, it was not possible to determine whether there were individual or environmental factors associated with the failure, or to what extent available maintenance documentation had been checked.

After correcting the oil line problem, there were further abnormal indications from the right engine, during a flight about 3 weeks after the initial occurrence. After landing, the reduction gearbox scavenge pump was found to be inoperative.

The ATSB’s final report notes that incorrect oil flow resulting from the transposed oil lines had damaged the engine’s air/oil separator, which increased the scavenge pump pressure. the reduction gearbox. This compromised the structural integrity of the bomb casing.

“These additional problems had not been detected during the initial maintenance,” Dr Walker said.

The report says that in 1990 the engine manufacturer, Honeywell, issued a service information letter stating that the oil lines had been transposed on several previous occasions on similar aircraft.

Following this event, the operator, Chartair, initiated a fleet-wide program to add markings to engine oil tanks, conducted toolbox discussions with engineering staff on distractions during maintenance and began documenting each stage of engine changes.

In addition, Honeywell reissued the Service Information Letter with additional information and guidance.

“This research highlights to maintenance engineers that it is important to check relevant documentation rather than relying on experience and memory, and to be familiar with other data such as manufacturer’s service information letters,” he said. Walker said.

“Furthermore, since maintenance documents do not always provide advice on non-routine technical situations, operators and maintainers should seek technical advice from the manufacturer to ensure that non-routine problems are fully resolved before putting service an aircraft”.