You may remember an article from last summer where Lake Speed, Jr. dyno tested his father’s vintage 358cc Cup engine from the 90s, only to find that the engine was severely underpowered. After some serious searching, some key issues were identified, but instead of fixing them and moving on, Speed decided to see how far they could push the engine with modern technology, while keeping the engine true to its initial form.

That means not fiddling too much with the vintage C3 heads, not changing the stroke, and generally keeping it as “original” as possible, while trying to get more than 480 horsepower. The speed had a number in mind at first, which was not revealed publicly, but behind closed doors was revealed to be both high and achievable (on paper) at the same time.

Put it back in the tobacco

This led to many companies stepping in to bring this engine straight into the 21st century, even though they were still using late 20th century components (I know, I know…I hate that term too). Our friend Billy Godbold envisioned a modern profile for a new COMP Cams camshaft, CP Pistons lifted some pistons to restore compression, and Total Seal incorporated proven 0.7mm piston ring technology to ensure that all combustion and engine oil stays where it is supposed to with a minimum of drag.

Two of the modernized parts of this engine rebuild were a modern camshaft profile and the taper, specific to the rings being used. In the last 25 years there has been great development in both fields, and significant power can be found only through optimization.

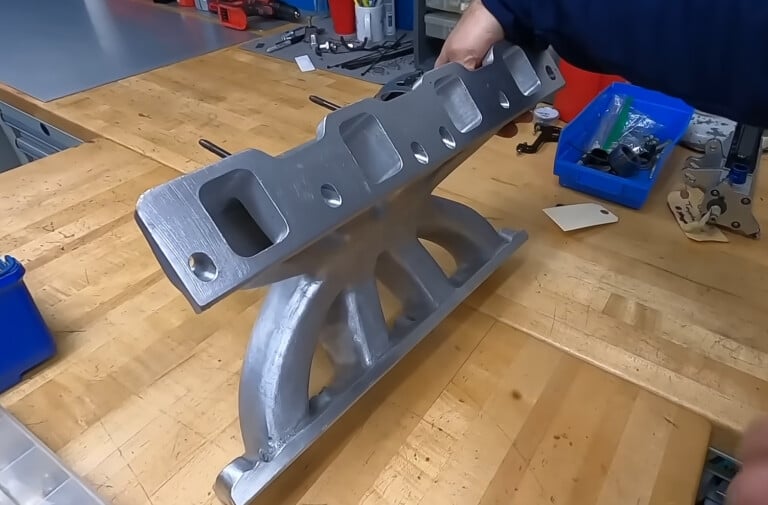

The vintage R-block was perfected by Pro Stock legend Greg Anderson himself with incredibly modern materials and techniques, and Pro Motor did it and brought the C3 heads and intake manifold in the best shape, in addition to mounting the engine with maximum precision. The team was able to reuse the original block, crank, connecting rods, cylinder head, intake manifold and oil pan, keeping the engine true to its roots.

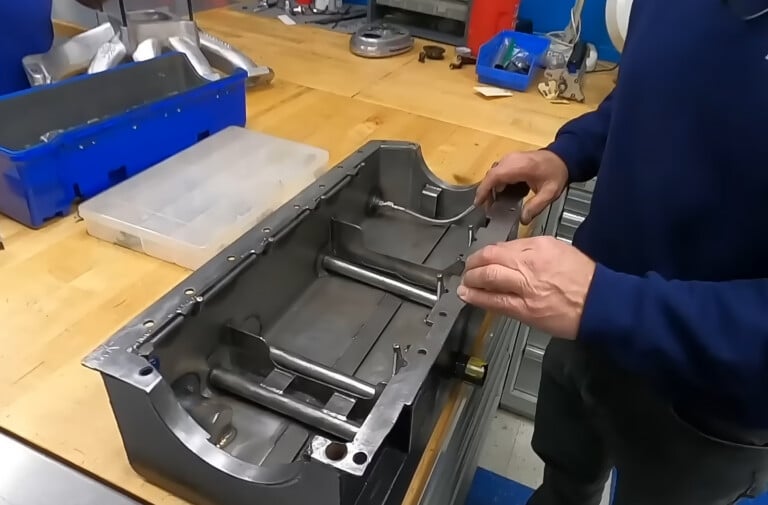

During the assembly process, PME’s Dennis Borem discovered that the engine’s oil sump was equipped with oil splashes, albeit disabled. “I didn’t look at the pan until we were ready to start mocking everything up to put it back together, and I noticed there were sprayers,” Borem says. There were no lines installed, and no provisions in the block to provide oil to the injectors, so they were never active on this engine. We got it plumbed up and running again, as well as adding a pick-up truck for the right turns, as this will be a road racing application.”

In addition to the head, block, crank and rods, the original oil pan and intake manifold were also reused. The C3 intake manifold had the runners opened up a bit to match some of the cleanup done to the C3 head intake ports as well as some rework to the plenum area using knowledge gained during the last few decades building competitive Cup engines. . The oil sump has oil jets built in from the start, but they were not connected. PME wired them up and ran them on the engine for this iteration.

Getting it on the Dyno

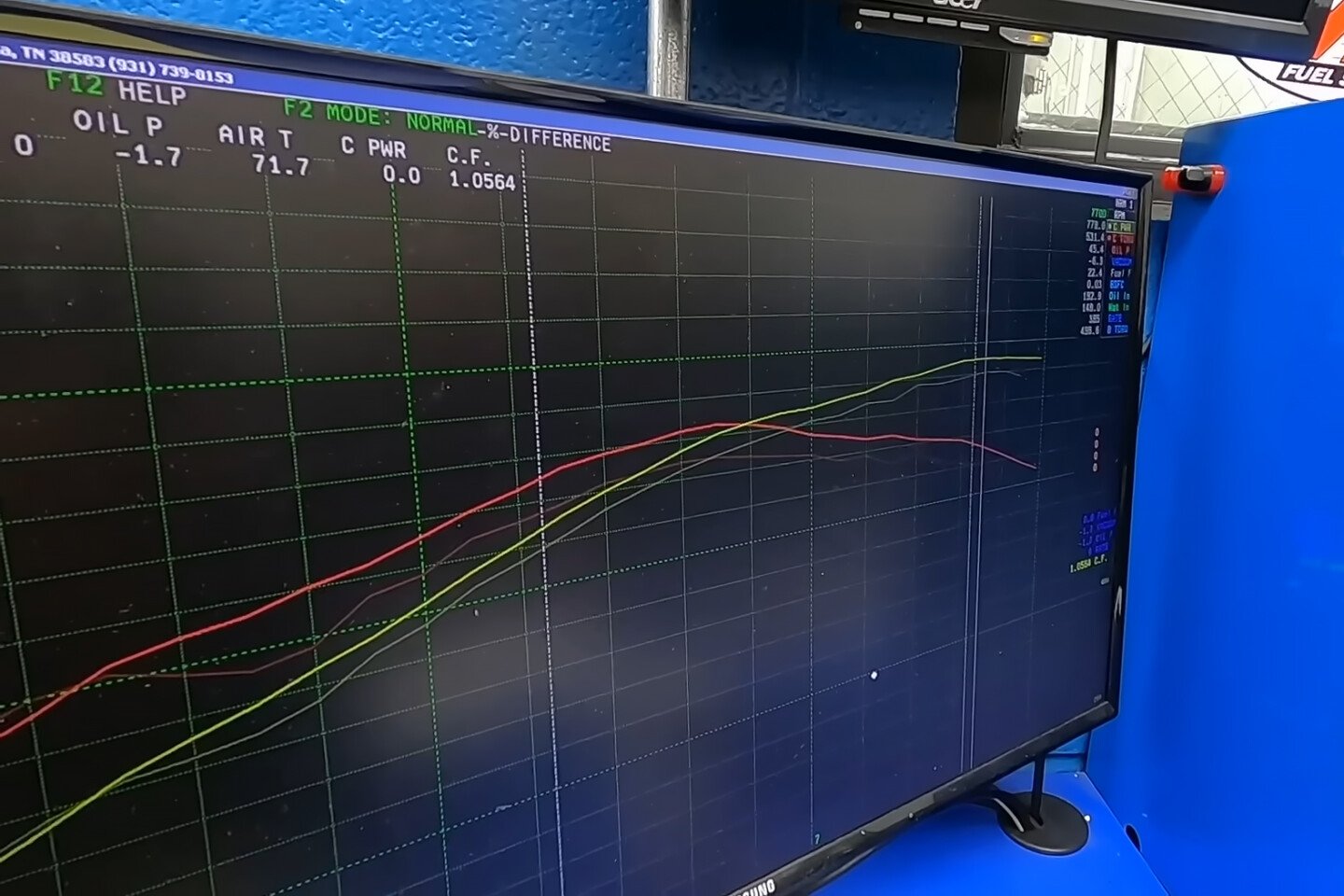

To break in the vintage engine on the dyno and make some early power runs, the PME team used Sunoco E15 unleaded gasoline, which is the current NASCAR-spec fuel. However, waiting for the bands was a big blue can of some VP Q16. With the engine ready to go, the first runs were easy sweeps. The bench showed 761 horsepower on the screen, with the unleaded gas and lube oil still in it. That number alone was well above the quiet target that was only confidently uttered months earlier and equates to a strong 2.12 horsepower per cubic inch.

But the team didn’t end there. As well as having a better fuel to try, there was the problem of getting a suitable carburettor on the engine. The engine’s old, used carburetor was still good, obviously, but this engine deserved better than good. So Lake went to Bill Pink for a proper carburetor, and it was time for a change. Peak numbers remained the same, but there was a five-horsepower increase across the board, with a slightly stronger increase around 5,500 RPM.

The Bill Pink carburetor didn’t add any peak power, but it definitely increased the curve from 5,500 rpm.

Then switching to VP Racing Q16 fuel found 10 more horsepower, both tip and through the curve, for 770 horsepower. From there the bearing oil was drained and Joe Gibbs Racing 0W-16 oil was poured into the engine. “That oil should be worth about four horsepower in that engine,” Speed, Jr. says. “We also did a jet change, so this may not be entirely accurate.”

The final run showed 779 horsepower (or 2.17 hp/ci) from this vintage race engine, completing this incredible project. So to recap, that’s an 18 horsepower increase from start to finish on test day from the Q16 oil and 0W-16. That’s an 89-horsepower increase from when the engine was in its prime in the ’90s (690 horsepower when it came out the door, originally), meaning the modern technology meant a power increase of 13.1 percent.

The big increase, however, comes from the power it got when it was taken out of the car and tested earlier this year. There it only made 480 horsepower. A number so low that it started this whole project. From that test session, the engine picked up 300 horsepower, or a 62.5 percent increase. It’s pretty impressive what a little technology and know-how can tell on the dyno.

Here you can see the difference between just the first and last bench roll of the day. 19 horsepower with only Q16 fuel and oil change. Actual gains are between the original dyno when the engine was new (690 horsepower), the dyno last summer (480 horsepower), and the final dyno at PME (780 horsepower power). This shows PME’s ability to build a good performing engine, regardless of its era.